MANAGING PLANTS, PROCESSES AND DATA

Using modern industrial systems calls for advanced and custom-optimized plant automation. Our customers benefit from our extensive, in-depth knowledge here, which we apply directly to our solutions in this area.

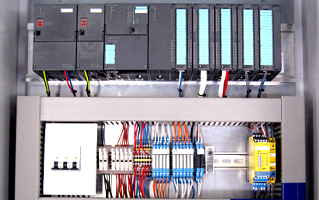

PLC programming

Following detailed analysis and close consultation with the customer, our specialists define the necessary automation tasks and create a specification. This forms the basis of programming tasks.

To implement requirements, we use proven software and high-quality hardware. This ensures that plants can be operated safely.

If required, we can provide customer-specific interfaces with special protocols for third-party systems.

Automation systems

Our electrical engineers have many years of experience and specific industry expertise. This allows them to provide tailored solutions for even highly complex processes. By deploying innovative automation elements, our specialists develop safe, cost-effective plant technology that is state-of-the-art.

SCADA systems

Functionality and the way the visualization system will look are determined in conjunction with the customer. By using the latest software, controlling and monitoring operational processes is designed to be straightforward. With system networking, it is possible to manage and monitor plant processes from different locations.

Processing tank terminal data

Our portfolio includes business systems that can be used to administer day-to-day operational data in a database. The system will generate delivery slips, cargo lists according to customer-specific parameters, as well as daily, weekly, monthly or annual reports.

Integrating certain components allows our engineers to perform remote maintenance on all automation systems.